Additional Information

Job ID: #SDK_005

Experience: Entry to Senior Level

Salary: DOE $25.00 to $35.00 USD

Contract type: Full-time

Location: Oil Patch USA

Job Activities

What you will do:

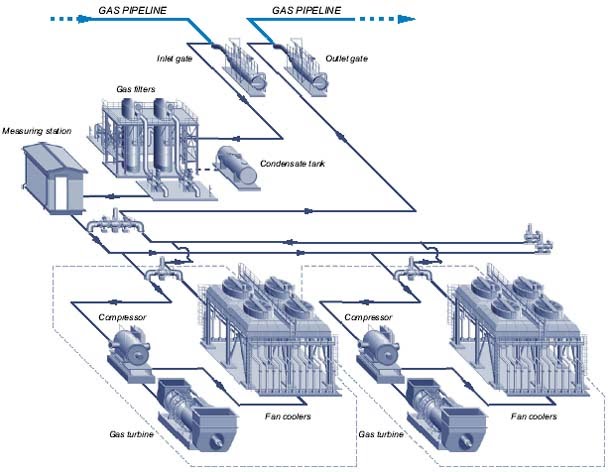

Reporting to the District Operations Manager, the individual must be experienced in service and maintenance of gas engine compressor packages and associated equipment for multiple applications.

Position requires strong mechanical abilities with knowledge and experience to perform complex multiple service and maintenance tasks. Candidate must be able to skillfully use a variety of manual, power, and technology tools in the completion of maintenance and service jobs. Ideal candidate would be certified as technician at some level for multiple types original equipment. Candidate must be familiar with associated stationary on/ off skid vessels, instruments and controls as they are related to gas processing plants, piping, welds and corrosion behaviors concerning compressor packages.

Position may require limited travel. Individual must be a self-starter and have the ability to provide clear concise daily reports on tasks related to his/her assignment. Must be able to represent in a professional manner.

Candidate must be a safe worker with strong working knowledge of Health, Safety and Environmental (HSE) procedures including; basic OSHA (Occupational Safety and Health Administration) standards, Best Practices and Local and Governmental Regulations pertaining to Domestic local, state, and federal requirements.

Candidate must have a basic understanding of the properties of both natural gas and associated liquids to work safely in hazardous and or toxic environments.

Responsibilities:

- Able to perform monthly preventive maintenance and minor repairs independently.

- Provide preventative and corrective field mechanical service on gas compression, process, and/or production equipment on site at client locations.

- Able to complete troubleshooting and repairing equipment, packages, and systems.

- Able to interpret Compressor Performance runs.

- Provides labor, guidance, and coordination required for immediate repair needs and major equipment overhauls and operation.

- Identifies and addresses equipment, package, and plant inefficiencies/issues.

- Provides 24/7 coverage.

- Works occasional overtime and is available for rotational call outs.

- Maintain and grow customer relationships.

- Takes initiative and fulfills duties consistent with company standards, policies, and controllable expense budget.

- Provides input to Supervisor on personnel and materials needs to provide optimal job planning.

- Assist in equipment Start-up/Commissioning.

- Knowledgeable of Purging and loading practices/procedures.

- Performs the job activities in a manner consistent with the projects goals and objectives.

- Completes proper reports/actions required by the location’s operating policies including the completion of Daily Service Reports.

- Stops activities that are unsafe for personnel or the environment when they occur or about to occur.

- Participate fully in the Job Safety Analysis (JSA) program.

- Participate in Behavior-Based Safety programs (BBS).

- Report all incidents immediately to supervisor.

- Participate fully in OSHA incident reporting and investigation program as well a customer’s incident reporting and investigation program

- Participate fully in site specific Emergency Action Plans.

- Recognizes and complies with Health, Safety and Environmental rules and policies that are applicable to each location.

The employer reserves the right to revise or change this description. This description does not constitute a written or implied contract of employment. All employees are expected to work varying hours of compensated overtime to accomplish various duties. All employees are expected to work rotating hours, shifts, or in different departments to accommodate the business demands. To perform this job successfully, an individual must be able to satisfactorily perform each of the above essential duties and meet the physical demands. Reasonable accommodations may be made to enable individuals with disabilities to meet these conditions.

Mid-Stream Oil & Gas

Mid-Stream activities include the processing, storing, transporting and marketing of Oil, Gas, and natural gas liquids,

These opportunities, to work for best in class, nationally recognized companies to advance your career doing interesting work within small cohesive teams, extensive training, and the opportunity to take your career wherever you want it to go!

Our client offers you the support and stability of a truly global organization meeting your life work balance needs. If you enjoy working with industry-leading cutting edge machinery, and have a can do personality, this is the place and culture for you. We have fantastic opportunities across these organizations.

- Email: tkernan@sdkhires.com

- Phone: 337.340.4923

- Address: Houston< Texas